Have you ever wondered about the materials that make modern construction projects possible? Geosynthetics are these hidden heroes. Let’s dive into what they are and how they’re changing the construction landscape.

Geosynthetics are synthetic products used in geotechnical engineering and construction. They mainly include geotextiles, geomembranes, geogrids, geonets, geocells, and geofoam. Geosynthetics serve various functions like separation, reinforcement, filtration, drainage, containment, and erosion control in civil engineering projects.

Curious about how geosynthetics work and why they’re so crucial in construction? Let’s explore their types, functions, and impact in greater detail.

Types of Geosynthetics

Geosynthetics, with their varied forms, play a critical role in modern construction and engineering. Here’s a closer look at each type and its specific functions:

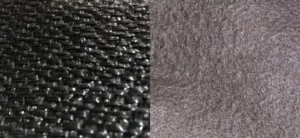

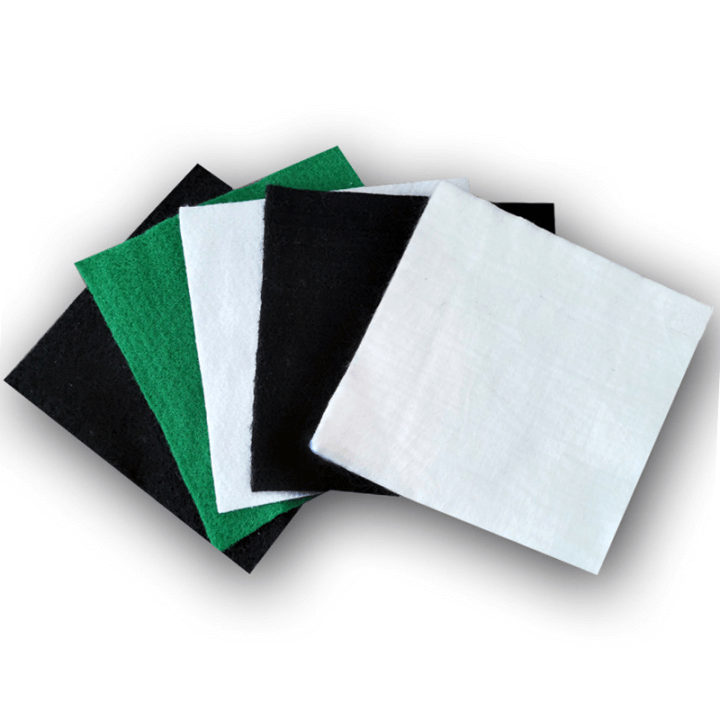

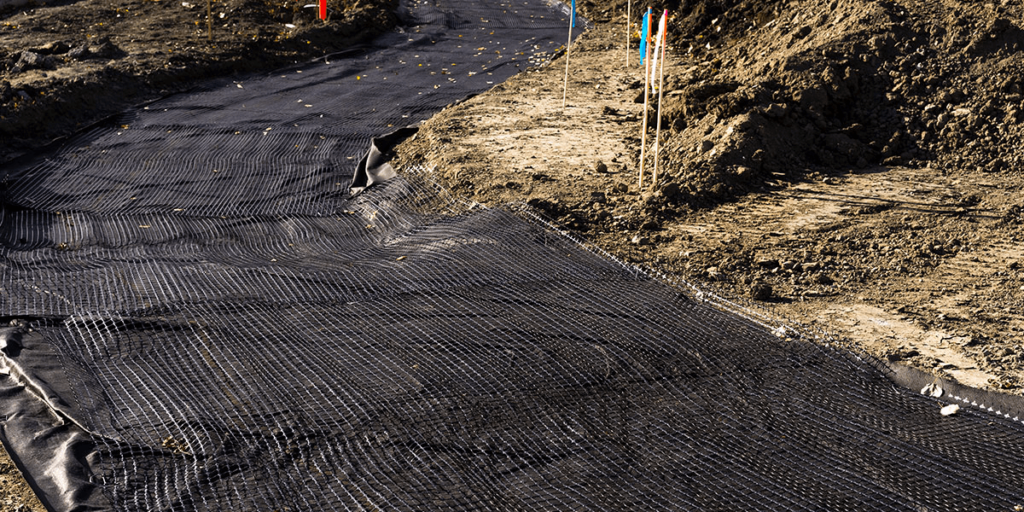

Geotextiles

Think of these as the multitaskers in the geosynthetic family. Made from synthetic fibers woven or non-woven, geotextiles are incredibly versatile. They’re primarily used for soil separation—keeping different soil layers distinct and intact. They also provide stabilization, ensuring that structures like roads and embankments remain stable over time. In terms of filtration, geotextiles prevent soil erosion while allowing water to drain through, making them ideal for drainage systems and erosion control measures.

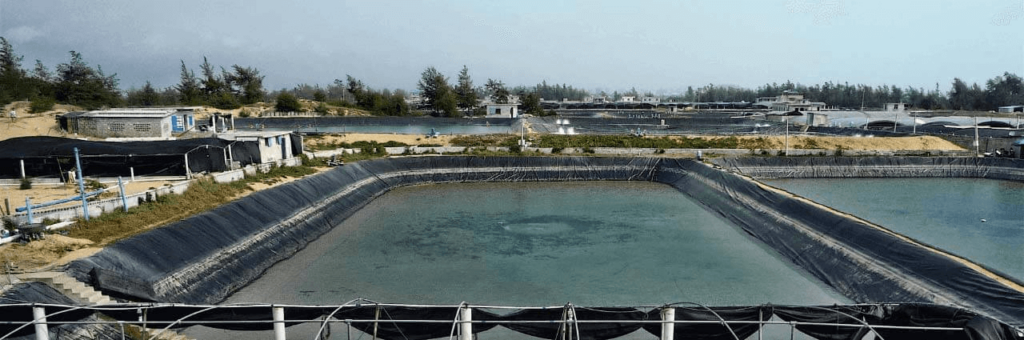

Geomembranes

These are the barrier guards. Geomembranes are made from relatively impermeable materials like HDPE, PVC, or EPDM. Their main job? Containment and waterproofing. They’re extensively used in environmental applications like landfill liners, water reservoirs, and for the containment of hazardous or liquid waste. Their impermeability is a key characteristic, ensuring no unwanted seepage or contamination occurs.

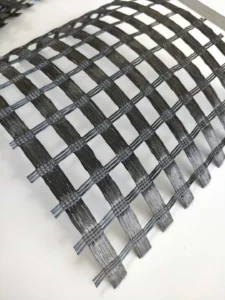

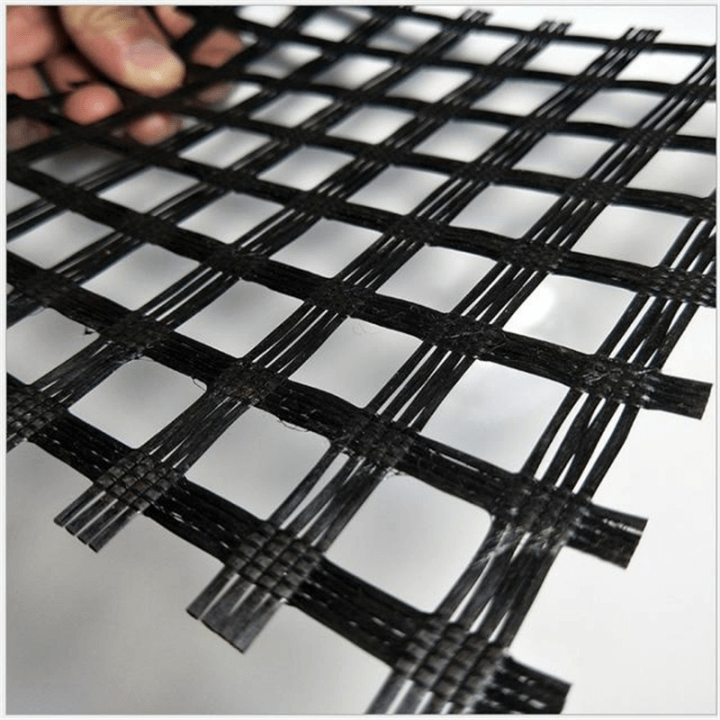

Geogrids

The structural supporters. Geogrids are grid-like structures, usually made from polymers like polyester or polyethylene. Their primary function is reinforcement. Imagine reinforcing a wall or a slope—geogrids do this but for soil. They’re used in roadway construction, retaining walls, and slope stabilization, helping to distribute loads and reduce pressure on underlying soils.

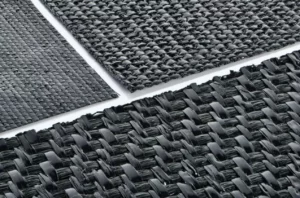

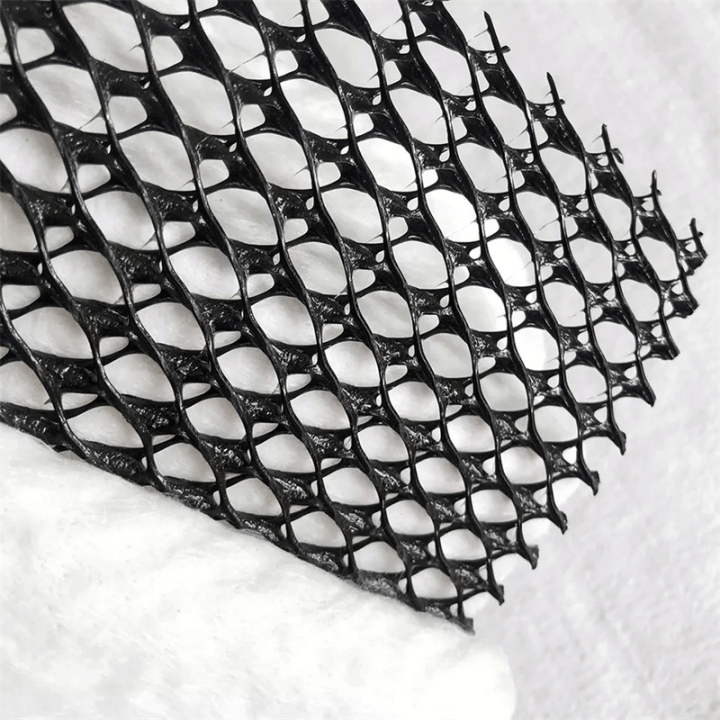

Geonets

These are the drainage facilitators. Constructed in a net-like manner, usually from polyethylene, geonets create channels for effective drainage. They’re often used in conjunction with geomembranes in landfill liners to facilitate leachate removal or in road construction for sub-surface drainage. Their design allows for efficient conveyance of fluids and gases.

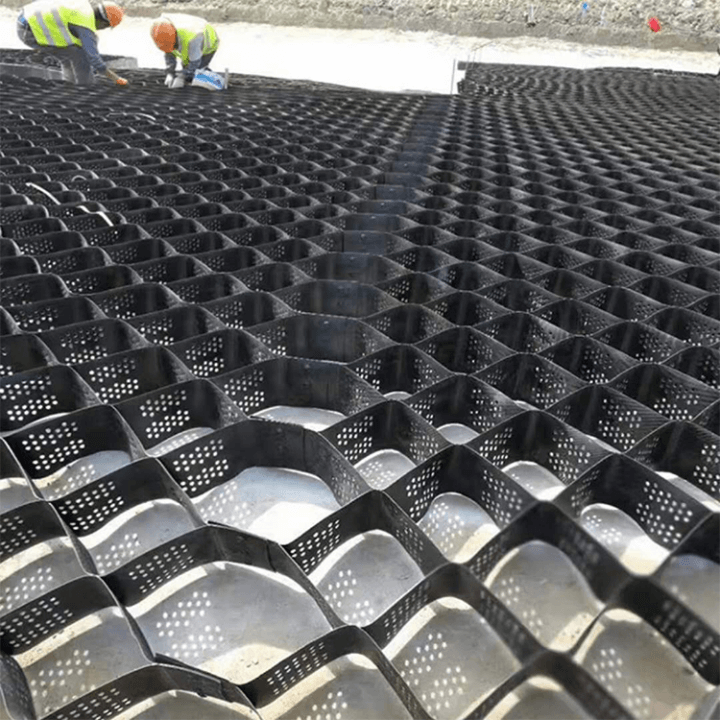

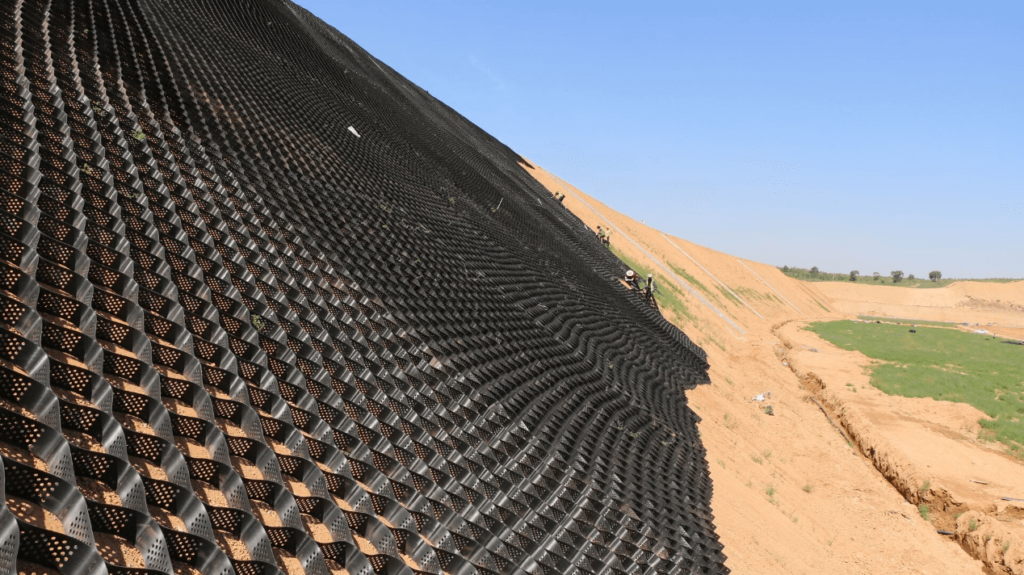

Geocells

Think of geocells as the 3D stabilizers. With their honeycomb-like structure, geocells confine and stabilize soils. Made typically from polyethylene or polyester, they’re used in slope protection, channel protection, and load support applications. Their cellular confinement systems are excellent for improving soil strength and preventing erosion.

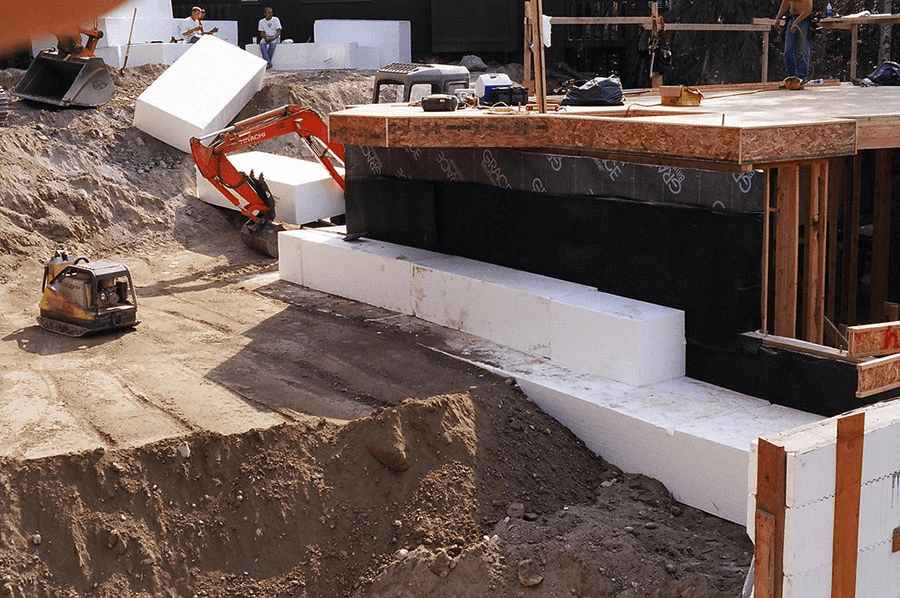

Geofoam

The lightweight fillers. Geofoam blocks, made from expanded polystyrene (EPS) or extruded polystyrene (XPS), are used as lightweight fill material. They’re particularly useful in projects where weight is a concern, like in bridge abutments, road construction over soft soils, or in landscaping. Their light weight reduces the load on underlying soils, preventing settlement and stability issues.

Each of these geosynthetic types brings its unique set of properties to a project, enhancing soil characteristics, ensuring stability, and boosting the overall durability and longevity of construction endeavors. Their roles are crucial in ensuring that modern construction techniques meet the demanding needs of today’s engineering challenges.

Applications of Geosynthetics

Geosynthetics, due to their versatility and effectiveness, find applications in numerous areas of construction and environmental engineering. Here’s an expanded view of their primary uses:

Road Construction

In road construction, geosynthetics serve multiple roles. Geotextiles are used for soil stabilization, ensuring that the road base remains intact and unaffected by the movement of finer soil particles. Geogrids provide additional reinforcement, especially in areas where the soil is weak, increasing the load-bearing capacity and extending the life of the road. Geofoam, with its lightweight properties, is used in road embankments to reduce the load on underlying soils, especially in areas with problematic soils or in bridge approach fills.

Landfills

The use of geomembranes in landfills is critical for environmental protection. These impermeable liners prevent contaminants from seeping into the ground and groundwater, thereby preventing pollution and protecting the ecosystem. Geonets and geocomposites are often used above the geomembrane layer for efficient drainage and leachate collection, ensuring that liquids are properly channeled away from the landfill site.

Erosion Control

In controlling erosion, especially on slopes and embankments, geotextiles, geocells, and geogrids play a significant role. They help in retaining soil and supporting vegetation growth, which is crucial for natural erosion control measures. In hydraulic applications, like in the protection of riverbanks or coastlines, geotextiles prevent soil erosion while allowing water to pass through, thereby stabilizing these areas against water flow and wave action.

Drainage Systems

Geosynthetics are essential in creating efficient drainage systems. Geonets and geocomposites facilitate the removal of water from soil, reducing hydrostatic pressure and preventing waterlogging. In structures like retaining walls, underground structures, and roadways, proper drainage is crucial to maintain structural integrity and prevent damage due to water accumulation.

Reinforced Soil Structures

Geogrids and geocells are used to reinforce soil in the construction of retaining walls, bridge abutments, and steep slopes. Their inclusion improves the strength and stability of the soil, making it possible to build taller and steeper structures than would be possible with unreinforced soil.

Waterproofing and Containment

Geomembranes are used in reservoirs, canals, and ponds for waterproofing, ensuring minimal water loss through seepage. In hazardous waste containment, they prevent the migration of contaminants, thus safeguarding the surrounding environment.

Agriculture and Aquaculture

In agriculture, geotextiles are used for weed control, moisture retention, and to protect against pests. In aquaculture, geomembranes are used to line ponds, ensuring water retention and quality control.

These diverse applications showcase the integral role geosynthetics play in modern construction and environmental engineering, offering solutions that are both effective and environmentally sound. By leveraging their unique properties, engineers and constructors are able to tackle a wide array of challenges, enhancing the efficiency and sustainability of their projects.

Advantages of Using Geosynthetics

The use of geosynthetics in construction and environmental projects offers numerous advantages, making them a go-to choice for modern engineering solutions. Here’s a detailed look at their key benefits:

Cost-Effectiveness

Geosynthetics are highly cost-effective in comparison to traditional materials. Their use significantly reduces the need for natural resources like aggregate, sand, and stone, which are more expensive and environmentally taxing to extract and transport. The installation of geosynthetics is often simpler and quicker, which reduces labor costs and speeds up project completion times. Additionally, their durability means less need for maintenance and repairs, resulting in long-term savings.

Durability and Resilience

One of the most significant advantages of geosynthetics is their durability. These materials are designed to be resistant to a wide range of environmental factors, including UV radiation, chemicals, rot, and biological degradation. This resilience ensures that they maintain their functionality over long periods, even under harsh environmental conditions, making them ideal for applications in exposed or challenging environments.

Flexibility and Versatility

Geosynthetics offer remarkable flexibility and are adaptable to various engineering and construction needs. Their diverse range—from geotextiles to geomembranes and geocells—means they can be used in a multitude of applications, such as roads, landfills, erosion control, and drainage systems. This versatility allows for tailored solutions that can address specific challenges of a project.

Environmental Benefits

The use of geosynthetics supports sustainable construction practices. By reducing the reliance on natural materials, they help in conserving natural resources and minimizing the environmental footprint of construction activities. Their role in erosion control and stabilization helps protect landscapes and ecosystems. In landfill and waste containment applications, geosynthetics prevent contamination of soil and groundwater, thereby safeguarding the environment.

Improvement of Soil Properties

Geosynthetics can significantly improve the properties of the soil they are used with. They can enhance soil strength, prevent soil erosion, and aid in soil consolidation. This improvement in soil behavior allows for the construction of infrastructure in areas where the natural soil conditions would have otherwise been prohibitive.

Enhanced Safety

By increasing the stability and strength of soil and other construction materials, geosynthetics contribute to the overall safety of construction projects. They reduce the risk of structural failures, landslides, and other hazards associated with weak or unstable soils.

Ease of Installation

Many geosynthetic products are lightweight and easy to handle, making their installation quicker and less labor-intensive compared to traditional materials. This ease of installation not only speeds up the construction process but also allows for greater precision in implementation.

In summary, geosynthetics offer a blend of cost-effectiveness, durability, flexibility, environmental benefits, and safety enhancement. Their ability to improve soil properties and ease of installation further contribute to their widespread use in contemporary engineering and construction projects.

Choosing the Right Geosynthetic

Selecting the appropriate geosynthetic for a specific project is a critical decision that can significantly impact the project’s success. Here are some key factors to consider in this selection process:

Project Requirements

The foremost consideration is understanding the specific needs and goals of the project. This involves assessing the primary function the geosynthetic needs to serve—whether it is for separation, reinforcement, filtration, drainage, containment, or protection. For instance, a project requiring soil stabilization will benefit more from geogrids or geocells, while a project needing efficient drainage might opt for geonets or geotextiles.

Material Properties

Different geosynthetics have varying physical and mechanical properties that determine their suitability for specific applications. Key properties to consider include:

Strength: The tensile strength of the material is crucial, especially for reinforcement applications.

Permeability: This is particularly important for drainage and filtration applications. Geotextiles, for instance, come in varying degrees of permeability suited for different uses.

Durability: Consider the longevity of the material under project conditions, including resistance to UV radiation, chemicals, and biological factors.

Elongation: The ability of the material to stretch without breaking is important in applications where flexibility is required.

Environmental Conditions:

The local climate, soil conditions, and environmental stressors play a significant role in the selection process. Factors to consider include:

Soil Type: The type of soil (such as clay, sand, or silt) will influence the choice of geosynthetic, especially in terms of permeability and filtration properties.

Climate: Weather conditions like temperature extremes, UV exposure, and moisture levels can affect the performance and longevity of geosynthetics.

Chemical Environment: In areas with potential chemical exposure, such as industrial sites or contaminated soils, the chemical resistance of the geosynthetic becomes a critical factor.

Compatibility with Other Materials: It’s important to ensure that the chosen geosynthetic is compatible with other materials used in the project. This includes compatibility with soil types, as well as any other construction materials or chemicals that may be present in the environment.

Regulatory and Industry Standards

Compliance with relevant standards and regulations is crucial. This ensures the material meets the necessary safety, quality, and environmental protection requirements.

Cost and Availability

While not the primary concern, the cost and availability of the geosynthetic material can also be a deciding factor, especially in large-scale or budget-sensitive projects.

Expert Consultation

Given the complexity of choices and the technical nature of geosynthetics, consulting with industry experts or geotechnical engineers can provide valuable insights and guidance in the selection process.

By carefully considering these factors, you can make an informed decision on the most suitable geosynthetic for your project, ensuring that it meets both the functional requirements and the environmental and economic considerations of your endeavor.

Conclusion

In conclusion, geosynthetics are integral to modern construction, offering versatile solutions that boost efficiency, safety, and sustainability. Understanding their types, applications, and benefits is key for professionals to make informed decisions in their projects, harnessing these materials’ full potential. Remember, the right geosynthetic can make all the difference in your project’s success!