Dive into the world of warp knitted polyester geogrids, a groundbreaking material revolutionizing geotechnical engineering with its unparalleled strength and versatility.

Warp knitted polyester geogrid is a high-strength, durable fabric, produced by warp knitting polyester yarns. It’s used in soil stabilization, slope reinforcement, and retaining walls, enhancing structural integrity and sustainability in construction.

Keep reading to explore the detailed fabrication process, unique material characteristics, and diverse applications of warp knitted polyester geogrids in modern construction.

What is Warp Knitted Polyester Geogrid?

Warp knitted polyester geogrid is a fascinating and innovative material, ingeniously engineered to address complex challenges in geotechnical and civil engineering. Here’s a more in-depth look at its unique features:

Fabrication Process:

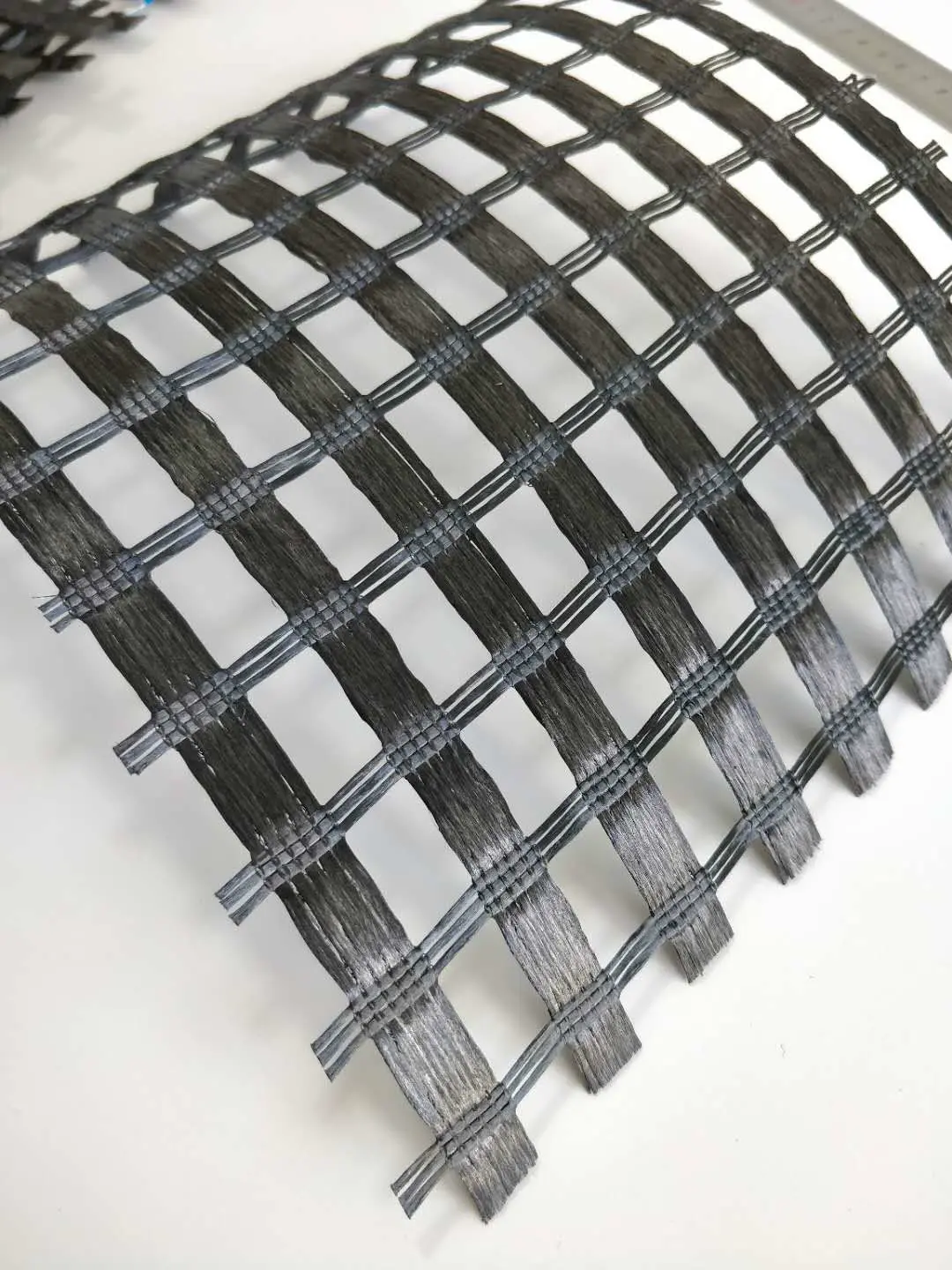

Knitting Technique: The geogrid is produced through a specialized warp knitting process. In this method, polyester yarns are interlaced in a longitudinal direction, or ‘warp’, creating a strong and consistent fabric.

Enhanced Strength: This method of knitting not only aligns the yarns for uniform stress distribution but also binds them tightly, significantly enhancing the material’s overall tensile strength and stability.

Material Characteristics:

Polyester Advantages: Polyester is selected for its exceptional strength-to-weight ratio, making the geogrid lightweight yet incredibly strong. It also exhibits superior durability, able to withstand harsh environmental conditions without degrading.

Material Strength: The geogrids come in various strengths, with longitudinal and transverse strengths ranging from 25 KN/m to 100 KN/m, accommodating different engineering needs.

Environmental Resistance: The inherent properties of polyester, combined with the warp knitting technique, render the geogrid highly resistant to UV rays, moisture, and chemicals. This resistance ensures that the geogrid retains its integrity and functionality over long periods, even in adverse conditions.

Structural Design:

Grid Configuration: The warp knitting process results in a distinctive grid-like structure. This configuration is crucial for the geogrid’s functionality, as the open grid allows for excellent interlocking with soil, aggregate, or other fill materials.

Load Distribution and Stabilization: The interlocking mechanism significantly enhances soil stabilization. It distributes loads more evenly and effectively, reducing the risk of soil displacement and settling. This is particularly beneficial in applications like roadway foundations, where load distribution is key to longevity and safety.

Flexibility and Adaptability: Despite its strength, the warp-knitted polyester geogrid retains a degree of flexibility. This allows it to conform to varying terrain and soil conditions, making it suitable for a wide range of applications, from flat landscapes to undulating terrains.

By understanding the intricate details of warp-knitted polyester geogrid’s fabrication, material characteristics, and structural design, one can appreciate its role in modern construction and engineering projects. Its combination of strength, durability, and adaptability makes it an invaluable resource in enhancing the stability and longevity of various geotechnical applications.

Applications and Benefits of Warp Knitted Polyester Geogrid

Warp knitted polyester geogrids are a cornerstone in contemporary construction and civil engineering, offering a plethora of applications and benefits. Let’s explore these in greater detail:

Soil Stabilization:

Road Construction: In road construction, especially on weak or unstable subgrades, these geogrids play a critical role. They enhance load distribution, effectively reducing pressure on the subgrade and thus prolonging the road’s lifespan.

Subgrade Improvement: By integrating with the soil, they improve its overall bearing capacity, reducing the likelihood of settlements and rutting, common issues in unpaved and paved roadways.

Slope Reinforcement:

Erosion Control: These geogrids are instrumental in stabilizing slopes. They prevent soil erosion and landslides, especially in areas prone to heavy rains or seismic activity.

Vegetation Support: The grid structure allows vegetation to root more effectively, promoting greener, more stable slopes. This is essential for ecological restoration projects and landscaping.

Retaining Walls:

Structural Support: In constructing retaining walls, warp knitted polyester geogrids provide essential tensile strength, helping the walls resist the lateral earth pressures.

Flexibility in Design: Their use enables more flexible design options, including taller and more complex wall structures, often with cost-saving implications.

Environmental Benefits:

Sustainability: These geogrids are a more sustainable alternative to traditional construction materials like concrete and steel. By reducing the need for quarrying and the associated environmental impact, they present a greener solution.

Carbon Footprint Reduction: Their lightweight nature and ease of installation mean lower carbon emissions in transport and construction processes, contributing to more environmentally friendly construction practices.

Additional Applications:

Pavements and Parking Areas: They are also used in the construction of pavements and parking areas, enhancing the load-bearing capacity and preventing surface deformation.

Foundation Support: For buildings and other structures, warp knitted polyester geogrids can be used to reinforce the foundation, especially in areas with challenging soil conditions.

Innovation in Construction:

Advanced Engineering Solutions: The integration of these geogrids into various construction projects represents the innovative use of advanced materials in engineering, leading to smarter, more sustainable, and cost-effective solutions.

Warp knitted polyester geogrids, therefore, are not just materials but integral components that enhance the structural integrity and sustainability of a wide range of construction projects. Their ability to reinforce, stabilize, and protect while being environmentally conscious makes them an invaluable asset in modern engineering and construction.

Construction Method for Warp Knitted Polyester Geogrid

The effective installation of warp knitted polyester geogrid is critical for maximizing its benefits in construction projects. Here’s a comprehensive guide on the construction method:

Surface Preparation:

Leveling the Substrate: Start with leveling and preparing the original pavement or the intended surface. This involves finishing, trimming, and thoroughly cleaning the area to ensure a smooth and stable base for the geogrid.

Laying the Geogrid:

Proper Placement: Carefully lay the geogrid on the prepared surface. It should be laid on a coarse-grained stone layer or directly on the prepared soil, depending on the project’s specifications.

Alignment: Ensure the geogrid is properly aligned with the direction of the expected load or traffic flow for optimal performance.

Securing the Geogrid:

Fixation: For ordinary geogrids, use special steel nails or suitable fixing methods to secure the geogrid in place. This step is crucial to prevent shifting or wrinkling of the geogrid under load.

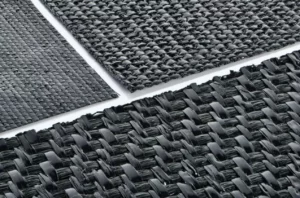

Overlapping: If multiple strips of geogrid are used, ensure they are overlapped correctly, usually by more than 5 cm horizontally and greater than 10 cm in length, to provide a continuous reinforcement layer.

Application of Bitumen (if required):

Minimal Use: In cases where bitumen-treated geogrids are used, sprinkle as little bitumen sticky oil as possible. This helps in creating a better bond between the geogrid and the overlying layers.

Rolling and Pressing:

Compaction: After laying the geogrid, it should be moderately rolled using rubber wheel rollers. This compaction helps in embedding the geogrid into the base layer and ensures proper contact and interlocking.

Asphalt Mixture Paving:

Covering Layer: Once the geogrid is secured and compacted, proceed with paving the asphalt mixture. This final layer should be applied and compacted to form a solid and stable road surface.

Post-Installation Inspection:

Quality Check: Conduct a thorough inspection post-installation to ensure the geogrid is well-secured and the overlying layers are properly compacted. Any discrepancies should be addressed immediately to maintain the integrity of the construction.

By following these steps, the warp knitted polyester geogrid can be effectively integrated into various construction projects, enhancing soil stabilization, load distribution, and overall structural strength. Proper installation ensures that the geogrid functions optimally, contributing significantly to the project’s success and longevity.

CONCLUSION

In conclusion, warp knitted polyester geogrids are a testament to innovation in civil engineering and construction. By integrating these geogrids into various projects, engineers and builders can achieve enhanced stability, durability, and eco-friendliness. The material’s high tensile strength, low elongation, and resistance to environmental factors make it a superior choice for reinforcing soil and structures. Its versatility across applications, from road construction to slope reinforcement, reflects its ability to adapt to diverse engineering challenges. Adopting warp knitted polyester geogrids is a step toward smarter, more sustainable, and cost-effective construction practices, paving the way for a more resilient and durable infrastructure.