Dive into the world of geotextiles and discover the distinct advantages of woven and non-woven types. This guide is your key to understanding which geotextile fits your project needs perfectly.

Woven geotextiles offer high tensile strength and are ideal for soil stabilization and reinforcement, suitable for roads and embankments. Non-woven geotextiles excel in filtration and drainage, making them perfect for erosion control and landscape projects.

Join us as we unravel the intricate details of each type of geotextile, exploring their unique properties, applications, and how they contribute to the success of your construction and landscaping endeavors.

The Fabric of Success: Woven Geotextiles – Enhanced with Additional Details

What is Woven geotextiles ?

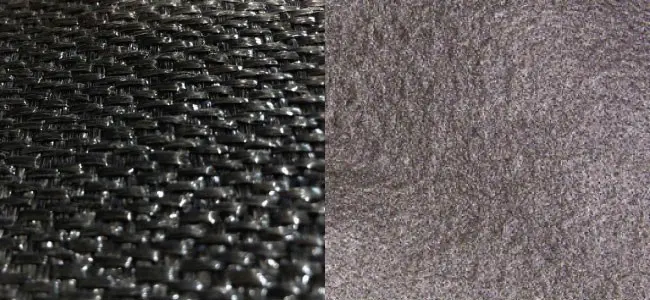

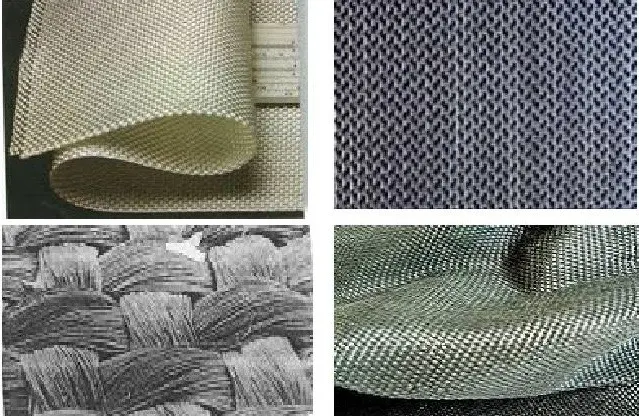

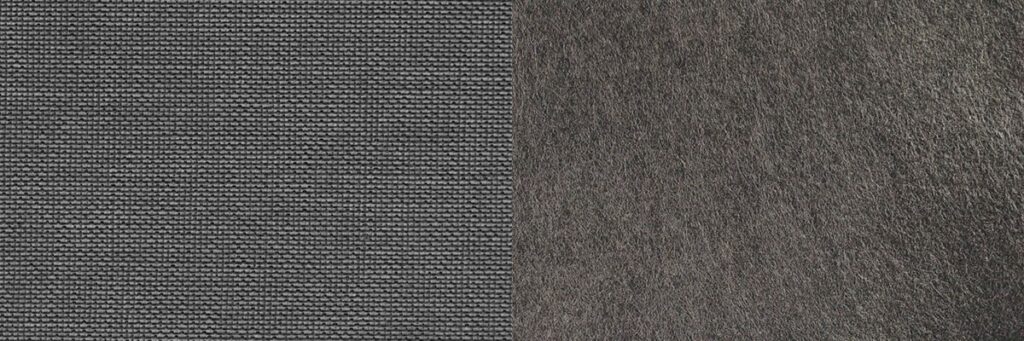

Woven geotextiles are a type of geosynthetic material, ingeniously crafted by interlacing two or more sets of yarns or filaments. These yarns, running parallel in different directions, are intricately woven on looms to form a fabric-like structure. The yarns that run lengthwise in the roll are known as warp yarns, forming the backbone of the fabric’s structure. In contrast, the weft yarns, woven in and out of the warp yarns, run across the width of the roll.

The weaving process of these geotextiles can be varied, using different techniques such as plain, twill, or satin weave. Each of these weaving methods offers unique characteristics to the geotextile, affecting its strength, permeability, and durability. The plain weave is the simplest and most common, providing a balanced structure. Twill weave allows for a denser fabric, enhancing strength, while satin weave offers a smoother surface.

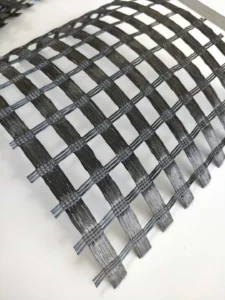

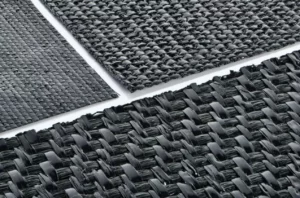

Types of woven geotextiles

Two primary types of woven geotextiles are prevalent in the market: split film woven geotextiles, typically made from polypropylene (PP) material, and filament woven geotextiles, which can be made from either PP or polyester (PET). Split film woven geotextiles are known for their robustness and are often used in applications where high strength is required, such as in road construction. Filament woven geotextiles, on the other hand, offer higher flexibility and are preferred in scenarios where a combination of strength and deformation is needed.

In practical applications, the requirements for woven geotextiles can vary greatly. Therefore, these materials are available in different thicknesses and densities, tailored to meet specific project needs. The specification and quality control of woven geotextiles are governed by the standard GBT 17640-2008. The width of these geotextiles typically ranges from 1 meter to 5.2 meters, with 5.2 meters being the maximum width currently producible by Chinese factories.

What is the advantage of Woven geotextiles ?

This customization and variety in woven geotextiles make them an adaptable solution for various geotechnical applications. Whether it’s for soil stabilization, load distribution, or erosion control, the specific properties of woven geotextiles can be optimized to enhance the performance and longevity of civil engineering projects.

What sets woven geotextiles apart is their impressive tensile strength. They’re engineered to withstand substantial mechanical stress, making them ideal for applications where the ground needs to be stabilized under heavy loads. Think of constructing roads or railways, where the earth beneath must support the weight of vehicles and continuous traffic. Woven geotextiles spread the load evenly, preventing the ground from shifting and ensuring the longevity of the construction.

Additionally, their low elongation is a crucial feature. When these geotextiles are placed under stress, they stretch very little, maintaining their integrity and continuing to provide support. This characteristic is particularly important in situations like embankment construction, where maintaining shape and stability over time is critical.

But it’s not just about brute strength. Woven geotextiles also excel in permeability. They allow water to pass through while preventing the movement of finer soil particles. This quality is vital for managing erosion and maintaining soil health under paved surfaces.

Moreover, their durability makes them a long-term solution. Woven geotextiles resist rot, mold, and other natural elements, ensuring they last for years once installed. They’re also resistant to chemicals and UV radiation, making them suitable for a wide range of environmental conditions.

In summary, woven geotextiles are the go-to option for projects requiring robust, enduring support. Whether it’s for road construction, slope reinforcement, or coastal defense works, their strength, low elongation, and durability make them an indispensable part of modern geotechnical engineering.

Non-Woven Geotextiles: The Unsung Heroes – Enhanced with Additional Details

What is the Non-woven geotextiles ?

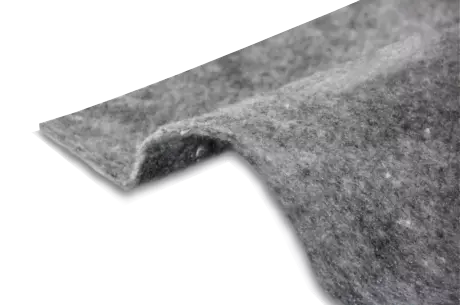

Non-woven geotextiles are a distinct category in the geotextile family, characterized by their unique fabrication process. Unlike their woven counterparts, non-woven geotextiles are made from either long fibers or short fibers bonded together in an irregular, non-interwoven manner. This bond is typically achieved through a combination of heat and pressure, creating a fabric with a distinctly different texture and set of properties compared to woven geotextile.

Types of Non-woven geotextiles?

The materials used for non-woven geotextiles can be classified into two main types: polypropylene (PP) and polyester (PET). These materials are further differentiated based on the length of the fibers used, resulting in long-filament and short-filament geotextiles. Generally, the width of these geotextiles ranges from 1 meter to 6 meters, with a recommendation to keep the size below 6 meters for optimal handling and performance, given their lightweight nature.

Introducing Common Types of Non-Woven Geotextiles

Short-Filament Needled Geotextile:

Material and Process: Made from polyester crimped short fiber or polypropylene fiber, typically 54-64mm in length. These fibers are transformed into a cohesive fabric through a non-woven production process involving steps like opening, carding, random interweaving, mesh laying, and needling.

Properties and Uses: These geotextiles are known for their resistance to acids, alkalis, and corrosion, as well as their durability and aging resistance. With high strength and stable dimensions, they are excellent for reinforcement, isolation, filtration, and drainage applications in sectors like water conservancy, highways, and railways.

Standards: Governed by GB/T 17638-2017, these geotextiles are a testament to quality and reliability in various engineering contexts.

Long-Filament Geotextile:

Material and Process: This type is produced from PP or PET long fibers through a process of spinning and needling consolidation. The fibers form a three-dimensional structure, with each fiber potentially spanning several meters. Typically ranging between 80-1000 g/m2, these geotextiles are notable for their superior mechanical properties, thanks to their longer fibers.

Performance: Long-filament geotextiles excel in both vertical and horizontal drainage, have excellent extensibility, and demonstrate high chemical stability, including resistance to biological factors, acids, alkalis, and aging. The variety in pore sizes and the intricate pore distribution enhance their permeability and filtration capabilities.

Standards: Adhering to GB/T 17639-2008, they ensure compliance with stringent quality benchmarks.

What is the advantage of non-woven geotextiles?

The primary advantage of non-woven geotextiles lies in their excellent filtration capabilities. They act as a sieve, allowing water to pass through while effectively trapping soil particles. This feature is crucial in preventing soil erosion in landscaping projects, protecting the integrity of structures like retaining walls, and managing water flow in drainage systems.

Their ability to separate different layers of soil and aggregates is another critical function. Non-woven geotextiles keep materials like gravel and finer soil layers distinct, preventing them from mixing. This separation is vital in road construction, where it’s essential to maintain the structural integrity of the base layers. Without this separation, roads and pavements could become unstable and prone to damage.

In addition to their primary functions of filtration and separation, non-woven geotextiles also offer excellent protection and cushioning. They can be used to protect waterproof membranes in roofing or landfill applications, reducing the risk of punctures or damage. This protective layer ensures the longevity and effectiveness of the waterproofing materials.

Moreover, non-woven geotextiles are highly adaptable and can conform to uneven surfaces, making them ideal for wrapping around pipes in drainage systems or fitting into irregular landscapes. Their flexibility allows for easy installation in a variety of settings, from small garden projects to large-scale civil engineering works.

In summary, non-woven geotextiles are essential for any project where filtration, separation, or protection is a priority. Their versatility, coupled with their filtration and protective properties, makes them an invaluable resource in various geotechnical applications, ensuring the stability and longevity of construction and landscaping projects.

Choosing the Right Geotextile for Your Project

The choice between woven and non-woven geotextiles can significantly influence the success of your project, akin to selecting the right tool for a specific task. Each type has specialized applications where it excels, tailored to meet various challenges in construction and landscaping.

Woven Geotextiles: The Foundation of Stability

Woven geotextiles, known for their high tensile strength and soil reinforcement capabilities, are particularly suited for:

Road and Railway Construction:

Stabilization Role: Serve as critical stabilizers, evenly distributing loads to prevent rutting and deformation.

Layer Placement: Typically positioned between the subgrade and aggregate layers to maintain road structure integrity under heavy traffic.

Earth Reinforcement:

Structural Support: Enhance the strength of retaining walls and slopes, combating soil displacement.

Tension Management: Bear tension forces effectively, a task that natural soil cannot accomplish alone.

Coastal and Riverbank Erosion Control:

Erosion Protection: Key in protecting soil from erosion in aquatic environments.

Embankment Reinforcement: Reinforce embankments and shorelines, crucial for preserving natural landscapes and preventing land loss.

Landfills and Waste Containment:

Foundation Support: Reinforce and stabilize landfill foundations, crucial for supporting substantial waste material weight.

Environmental Protection: Prevent contamination and protect the surrounding environment.

Non-Woven Geotextiles: Masters of Filtration and Drainage

Non-woven geotextiles, with their superior filtration capabilities, are ideal for:

Drainage Systems:

Efficient Water Management: Utilized in French drains, roadside ditches, and retaining walls.

Filtration Ability: Allow water passage while trapping soil particles, crucial for preventing drainage system clogging.

Erosion Control:

Soil Preservation: Play a vital role in erosion control strategies, especially under riprap or in slope stabilization.

Water and Soil Management: Enable water flow while safeguarding against soil loss, thus protecting the landscape integrity.

Landscape Projects:

Protective Layering: Act as protective and separating layers in gardens and landscaping.

Weed and Soil Management: Prevent weed growth through gravel paths, while allowing water and nutrients to permeate the soil.

Building and Construction:

Moisture Barrier: Serve as protective layers in roofing, insulation, and foundation moisture barriers.

Structural Longevity: Enhance the longevity of buildings by protecting critical structural elements from water damage.

In conclusion, understanding the distinct applications of woven and non-woven geotextiles allows for informed decision-making in construction and landscaping projects. Woven geotextiles are the go-to choice for projects demanding strength and stability, while non-woven geotextiles are preferred for their filtration, drainage, and protective qualities. Selecting the right geotextile type ensures more effective, efficient, and durable outcomes, aligning perfectly with the specific requirements of your project.

CONCLUSION

In summary, the choice between woven and non-woven geotextiles is pivotal to the success of various construction and landscaping projects. Woven geotextiles, known for their strength and stability, are best suited for heavy-duty applications like road construction and earth reinforcement. In contrast, non-woven geotextiles, with their excellent filtration and drainage properties, are ideal for scenarios where water management and soil preservation are key. Understanding these nuances enables informed decision-making, ensuring that the right geotextile is selected for each specific project, thereby optimizing performance, efficiency, and durability.